A unique thermoplastics additive manufacturing system

Advanced additive manufacturing capabilities

The Gigaprinter is a serial, industrial 3D printing system that utilizes and is fully compliant with VTPM technology. Following are some of its main features and capabilities:

Can extrude pellets (industry standard for thermoplastic output) and particles up to 4x4x4 mm in size.

Extruder temperature up to 500°C to melt all thermoplastics.

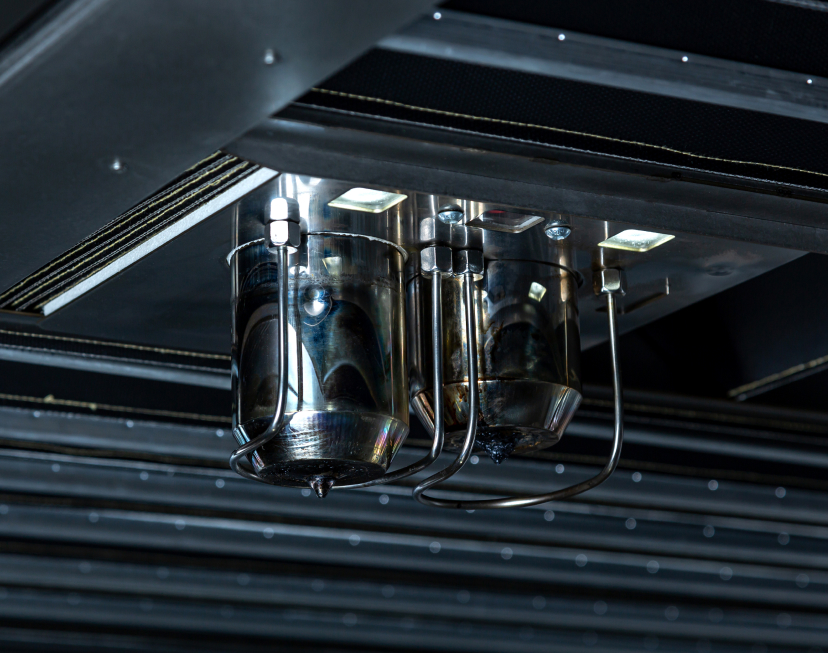

Universal and interchangeable extruder.

Relatively large volume working area 1785 x 1200 x 960 mm.

Wide adjustment of all basic printing parameters.

Interchangeable nozzles in various sizes from 0.4 mm to 4 mm.

Precise dosing of materials.

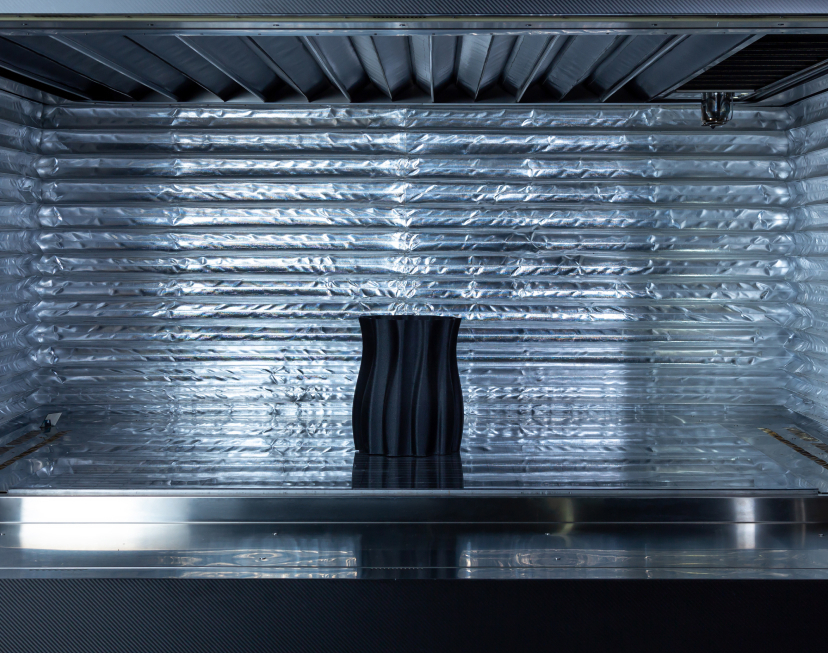

Adaptive thermal chamber with a wide range of parameters to maintain temperatures up to 120°C.

Kinematics capable of simultaneously providing high positioning accuracy, high travel speeds up to 12 m/sec, and high print head accelerations up to 1G.

Ability to adjust surface quality over a wide range.

Two extruders that can print with the same or different materials, for example:

Where a second material is needed to create supports which are later removed.

To print two different materials on the same layer.

With the same material but with different nozzle sizes, for example, a 0.4mm nozzle on one extruder for a highly detailed area, and a 4 mm nozzle where an area needs to be filled.

Where a second material is needed to create supports which are later removed.

To print two different materials on the same layer.

With the same material but with different nozzle sizes, for example, a 0.4mm nozzle on one extruder for a highly detailed area, and a 4 mm nozzle where an area needs to be filled.

Versatility and efficiency

These features and capabilities make it possible to work with the widest range of thermoplastics, creating large-sized products with high precision, quality and speed, solving many industrial production tasks in its class.

Gigaprinter rapidly builds large, strong, complex, light objects, either one-off or multiples, that traditional manufacturing equipment cannot make, reducing waste and costs.

Ideal for any size prototypes, short-run production, on-demand manufacture, and research of new materials and properties.

Gigaprinter rapidly builds large, strong, complex, light objects, either one-off or multiples, that traditional manufacturing equipment cannot make, reducing waste and costs.

Ideal for any size prototypes, short-run production, on-demand manufacture, and research of new materials and properties.

When selecting production equipment, in addition to its capabilities, an important factor is its efficiency. It can be defined as the cost of equipment per unit of output. This parameter is determined by the ratio of two values - the cost of equipment and the speed of production of a unit of product at the same quality.

So, for example, if the equipment is twice as expensive, but its production speed is three times higher, then this more expensive equipment is more efficient.

With this in mind, Gigaprinter has paid a lot of attention to the speed of quality printing. Today Gigaprinter has the fastest, high quality print speed in its class.

In addition, faster print velocity speeds up other production processes in the factory, making it more efficient.

So, for example, if the equipment is twice as expensive, but its production speed is three times higher, then this more expensive equipment is more efficient.

With this in mind, Gigaprinter has paid a lot of attention to the speed of quality printing. Today Gigaprinter has the fastest, high quality print speed in its class.

In addition, faster print velocity speeds up other production processes in the factory, making it more efficient.

Auxiliary equipment

The Gigaprinter AM system consists of a number of devices. It is supplied with pellet (particles) feeder, connection system to a printer as standard, and also with optional equipment such as a milling machine, air compressor, metal traps etc.

Other additional equipment can be tailored to the specific process.

Other additional equipment can be tailored to the specific process.